Fusion Splicing Equipment

Cable Preparation

Precautions

Cable to Splice Box Preparation

Anchoring the Optical Units

Optical Unit Preparation

Fusion Splicer Fujikura

This procedure ensures that the closure is air tight. Without using the green sealant kit air and more importantly water can travel freely through the OPGW strands.. Once water enters a closure the “life” expectancy of that location will be reduced below the 50 years it’s expected to preform. From the operators perspective it’s highly unacceptable to have any location be susceptible to future failures, especially failures that could have been prevented by doing it right in the beginning.

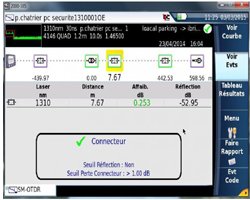

The MTS-4000 is a small, compact and handheld test platform designed for all phases of the network lifecycle, from the installation to the maintenance of Access/FTTx networks and triple-play services. With two slots available to integrate test modules of E4100 series, the MTS-4000 multiply the tests possibilities.

Fusion Splicing Equipments. Fujikura 80S Splicing Machine

JDSU MTS-4000 OTDR, we splice fiber cables accurately.

We have highly knowledged & experienced Splicers.

Fittings and Clousers

The FIBERLIGN Dead-end is designed to terminate Optical Ground Wire (OPGW) while minimising any compression stresses that may be transferred to the core or optical elements within.

The Formed Wire Dead-end uses two helically shaped formed wire components an inner layer of Structural Reinforcing Rods and an outer layer Dead-end component.

The current transfer tab provides direct electrical bonding between OPGW and a ground lead. The current transfer tab eliminates current transfer through components of the suspension unit.